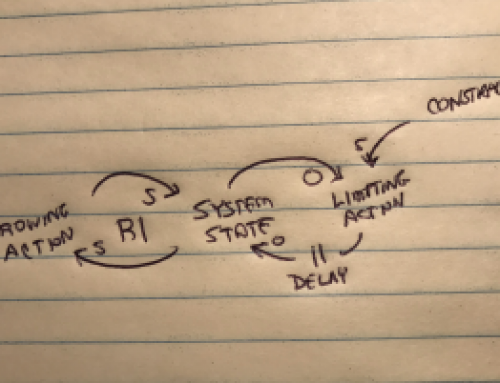

The first systems thinking building blocks we examined were the two types of feedback – reinforcing and balancing (see “Building Blocks of Systems Thinking: Obvious & Hidden Forces”). We are now going to take a close look at a building block that can be quite subtle and yet, have significant impact on your decisions and outcomes. That building block is called “delays” and can best be described as interruptions in a closed system between some cause and effect. In other words, when time passes between one action and resulting feedback, this is a delay. Another way to think about this is using the word “eventually.” This may resonate with many of you in business. You have probably been working through some decision or evaluating some process and recognized that certain actions definitely generate a result, but you might use the word “eventually” when describing the timing of those results.

An Example of Delays

One example of a system model with a delay that everyone will recognize is the very simple example of adjusting the temperature of your water in the shower. The figure to the right represents this balancing feedback loop with a delay. First, you recognize the balancing loop because there is a stated “balancing” goal of a desired temperature. The faucet (or faucets) is adjusted to control the temperature of the water until the desired temperature is achieved (balance). We all know that this is a process that also has a built in “delay.” Notice the two has marks on the connector between “Shower Faucet Setting” and “Current Water Temperature.” We know that when you adjust the faucet, there is a delay before you feel the change. Sometimes this delay is brief and sometimes it is much longer (especially true when you first turn on a shower on a very cold day).

A delay like this creates a situation where you can easily over-adjust one way or the other. Since you cannot get the true immediate effect because of the “delay,” you may think you have not adjusted enough and adjust a little more before you see the results of the prior adjustment. You know how this goes – back and forth until you finally get it right!

In Business, Delays Represent a Danger and an Opportunity

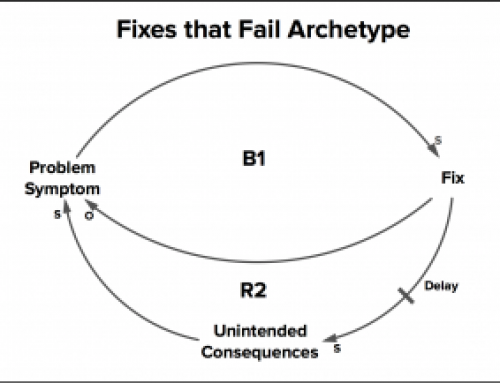

Delays are common in business. You invest in a new product today and believe that you will reap the benefits in the future. You hire a new salesperson but know that it takes time for that person to get up to speed in the territory. You commit additional resources to some specific project and then expect some delay in seeing any benefits. These types of delays are usually very apparent and acceptable. However, if you fail to recognize or perhaps underestimate delays, these delays can present a very real danger.

For example, if you don’t clearly recognize the presence of a delay between a decision and results, you may abandon your decision (actions) too quickly. Many entrepreneurs have greatly underestimated how long it takes to get a business started and given up too quickly. What about inaccurately calculating the delays regarding supply and demand? There is no doubt that many manufacturers have failed to time ramping up or ramping down manufacturing due to delays on the demand leading to misinterpreting the true demand. Delays also present a danger in “over-adjustment.” Without correct recognition of delays, it is easy to apply too much action or not enough action based on the feedback you see in the system.

The good news is that delays also present an opportunity. Ray Stata, former CEO of Analog Devices, wrote, “One of the highest leverage points for improving system performance is the minimization of system delays” (Organizational Learning – They Key to Management Innovation, Sloan Management Review, Spring 1989). At that time, American manufacturers were starting to think more about the time delays in supply vs. the accepted practices of tight inventory control and this gave rise to today’s modern “lean manufacturing” model. By focusing on ways to reduce delays on the supply side, manufacturers could better prevent having too much or too little inventory and focus on having the right inventory available at the right time, saving money and avoiding any undue delays in manufacturing.

Recognizing a possible delay in any system is the first step in capitalizing on an opportunity to create leverage. Taking specific actions to reduce the actual time of that delay can then greatly leverage success for that particular system (i.e., activity, project, product process, sales process).

Living with and Managing Delays

Delays exist in almost every feedback system. One could argue that there is always an imperceptible delay in any feedback mechanism and that argument likely holds water. For systems thinking purposes, the point is to identify delays that represent a real impact on the system. I know that if I was better at correctly managing the delay between eating and feeling full, I would likely be a bit thinner! So, how can I manage that delay? Eat more slowly so I can better measure the feedback considering that delay. There are various ways to manage delays in your business. Recognize business systems where delays are present and truly consider the impact of that delay. Consider if there are ways to reduce the delay. Learn to not “over-adjust” (over aggressive adjustments can cause instability) while ignoring the delay or underestimating that delay. The key is now you have an understanding of what to look for and they key factors involved in managing and/or leveraging delays in your own systems.